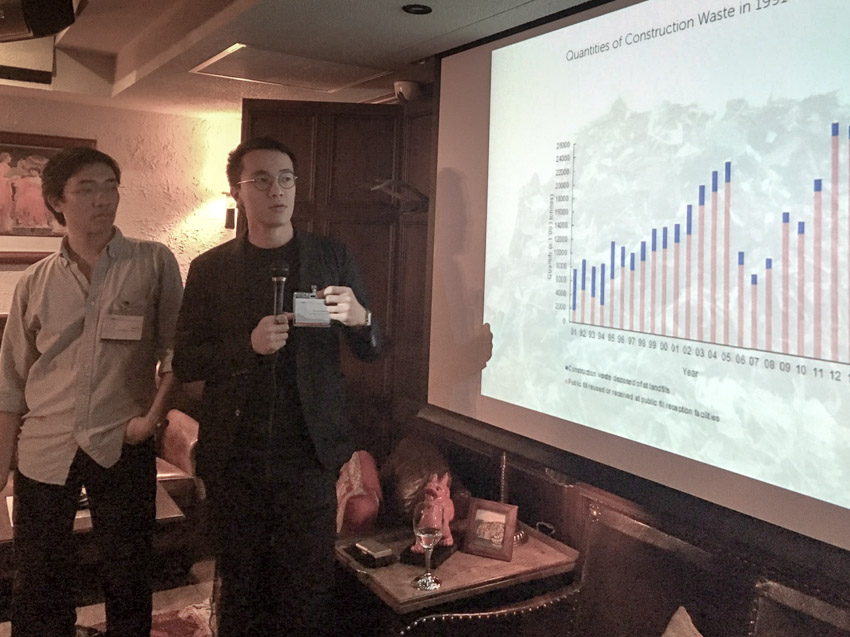

UPSOP presented Timber Scooper at a YAG event organized by AIAHK at Lan Kwai Lau. Much feedback were received from the crowd!

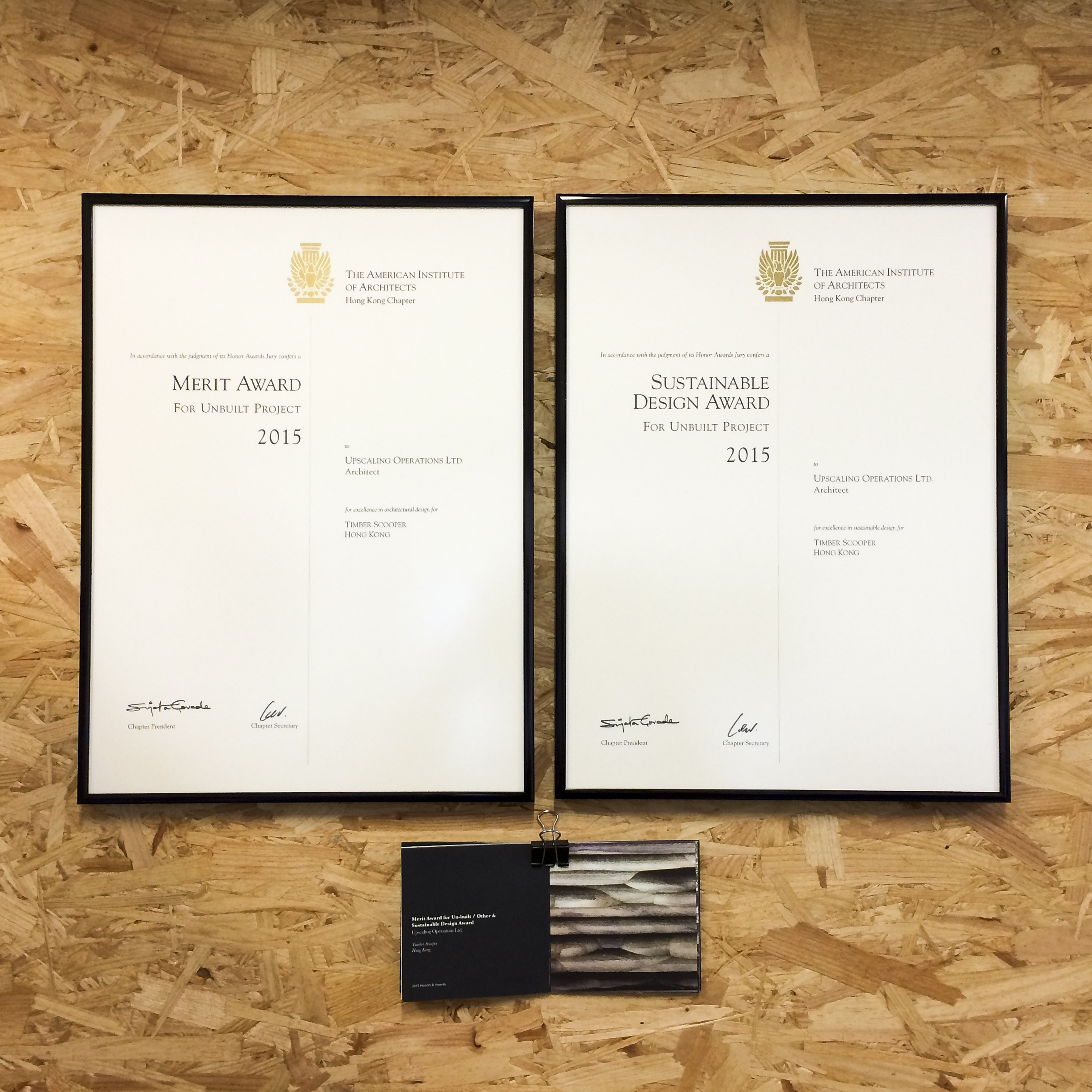

AIA Merit Award and Sustainable Design Award

We are thrilled to share the news that UPSOP received TWO awards form the American Institute of Architects Hong Kong!

UPSOP presented and exchanged ideas at the Asian Consortium 2015 with 100 other Asian social innovators! Our project is being exhibited at 10dayfest at PolyU.

http://www.10dayfest.hk/

Full day shooting at Cocoon, Common Ground and Cyberport for our upcoming product!

Our mobile display system @ Shin Kong Mitsukoshi 新光三越

When we compose geometries with one material, we play with shades of light and shadow.

Position: Design & Fabrication Assistant

We consider physical making crucial to the development of our ideas. Translation between digital and 1:1 mock-ups is therefore inter-wined in our design process. We are looking for candidates with the following skills:

- Strong design talent

- Strong passion for making

- Able to model design and manage production

- Fluent in Rhino, carpentry and prototyping

- Excellent communication and organization skills

If you are interested in this appointment, please send your CV; work sample/ portfolio; and salary expectations to:

Fabricating our improved mark 2 with taps and notches for the Mobile Display System. Plus a mini version this time!

Setting up our mobile display system [MDS #1] for backpack RAWROW at PageOne.

Our project was featured in the latest HKIA Journal under the theme Material and Detailing!

We received a lot of compliments about our up-cycling project for the salon. Thank you for the support! We hope the spirit of practicing green has reached you well with the rustic gold and brown palate. To continue the momentum we have created this name card stand to let you own a small piece! Interested? Click here for more information.

Our facebook page is finally launched!

Like our page!

UPSOP is shooting photos for the completed salon. With the ability to view shot photos on Ipad on-the-fly and using professional-grade gears including tilt-shift lens, we were able to capture high quality photos with instant decision making for framing and composition.

Installation of vertical fins for product displaying screen in progress.

Contouring of abandoned solid teak wood flooring panels in custom-made jigs.

Profiling of backing beams completed - 200 number of triangular plates with pockets for concealment of fastenings and embedding of metal angles.

We assembled the hardware for the CNC machine in a day, and spend another on figuring out the earthing of the mainframe and the 3 phased electricity. After days of setting up here comes the long awaited first spindle test!

Went off well but more tuning to come.

Our shipment has arrived!

Maneuvering 2 tonnes of steel was a true hectic.

Fab Lab partitioning completed. A hint of Japanese style.

Time for dinner.

Ideas kept on pouring.