Timber Scooper

Timber Scooper is a fabrication technique designed for recycling solid wood. It optimizes digitally the re-surfacing treatment of abandoned wood to create an organic 3D pattern. This scooping algorithm was designed to be open sourced for the use of other designers in order to promote sustainable design.

Teak flooring has been widely used from the 1950s onwards. When buildings are demolished, concrete is usually recycled for laying roads and foundation. However, rest of combustible construction materials go into landfill, including these valuable teak. The aim of Timber Scooper is to prolong the life-cycle of construction materials.

Timber Scooper

This design & fabrication project seeks to provide a way out to the wood recycling practice in Hong Kong. It promotes a more sustainable design methodology to be practiced by architects when using wood as material. Such design methodology runs parallel with a fabrication technique developed for the optimization of wood re-surfacing.

With the help of computation and digital fabrication, the architect can be well informed of the production, or re-production in this case, on construction materials and begins to take control over the fabrication process. Design decisions can be easily made based on the limits of the manufacturing process.

The aim of using recycled materials is to prolong the life-cycle of construction materials. It is often neglected by both the industry and the clients.

Demand and Opportunity

According to the Hong Kong Environmental Protection Department, around 300 tons of wood waste is produced every day. Recycling wood has not been an attractive industry in the city due to its low or negative return as a business. In cities of consumerism like Hong Kong, much high quality wood is used in construction especially for interior decoration. These interiors are required to be renovated and updated for keeping customers and maintaining competitiveness. This presents a high supply of abandoned wood and also a high demand for attractive wood products.

Saving Valuable Teak

Solid teak wood is one of the most expensive and rare construction material in the industry. It is one of the most desired lumber in the world due to its outstanding property. The natural teak oil makes the lumber very resistance to decay and termites and is suitable for both exterior and interior use. Abandoned teak wood is surprisingly seen quite often in Hong Kong in the form of wood flooring.

Digital Re-Surfacing

The fabrication technique was inspired by the re-surfacing process in the wood recycling industry. Recycling wood normally involves the collection and extraction of abandoned wood, followed by surface treatment. The worn surface of the recycled wood is planed by hand or with electric planers. The topmost surface is removed to give a uniform and level surface.

What if the process is done digitally by a computer numerically controlled router (CNC router)? Since CNC milling is a process of material removal, it can be used to planning the topmost unwanted layer while creating a 3-dimensional geometry for the wood surface.

Design Methodology for Generating Surface Geometry

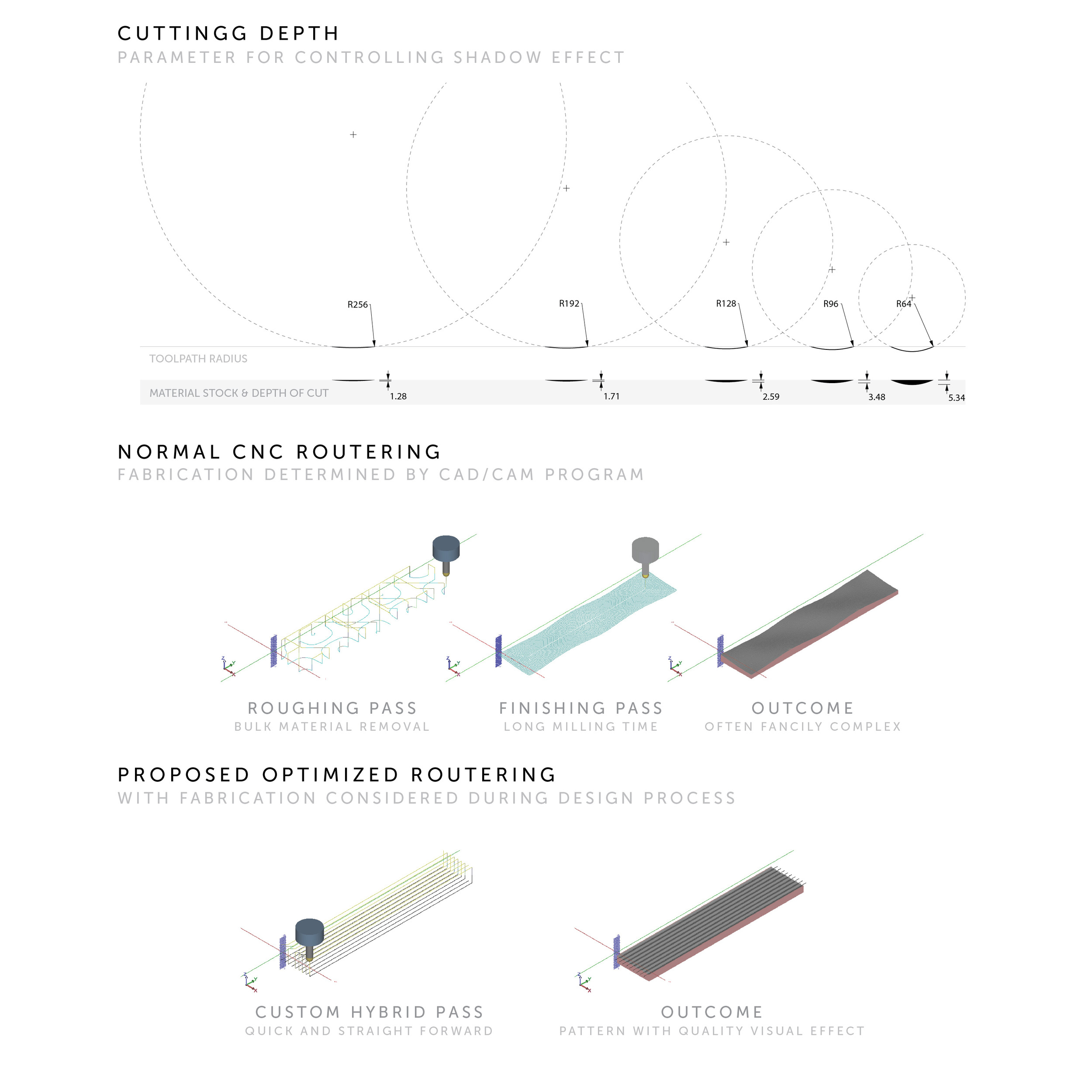

In architecture schools and normal practices, CNC routers are used to widen the possibilities of curved fabrication and precise manufacturing. The toolpaths are generated by the computer as direct translations of the designers’ creations. The whole fabrication usually takes much time as it is a retrofitting process of translating the freeform geometry into a feasible fabrication.

What if the design process begins with the limitation of the fabrication process? What is the most optimum geometry for cutting and for operating the machine? We developed a system of surface geometry that is highly connected to the operation of the CNC router. We were able to create an algorithm to generate toolpaths that are most optimized for the cutting tool and the machine. The main advantage of such is the short cutting time. The outcome geometry is basically the machine’s language.

Wood Scooping

The way how CNC operates is to take out material bits by bits from the stock with a spindling cutter. It follows a specific toolpath generated from a computer program. When a ball-nose cutter ramps in and climbs out of the material in a linear manner. It creates a shallow trench. When these paths overlaps with each other, a scooping effect arises.

Parametric design is incorporated to give architects the control of such pattern. The profile of the stroke, the depth of stroke, separation between strokes within a row and the distance to the adjacent row can all be controlled. Intersections of these strokes are unpredictable as the control of each scoop is independent. Wood re-surfacing by means of organized scooping will therefore create an attractive organic pattern.

Mass Custom Production

Mass production is possible when the whole router bed is fitted with recycled flooring panels slotted with each other. Multiple milling files can be combined into one to give individual customized geometries to each panels while lowering the cost of manual operation. Special jigs can be used to facilitate the process of loading and unloading and thus minimizing the idling time of the machine.

Tiling and Artwork Application

Recycled teak wood can be used in both exterior and interior as tiling panels. The toolpath can be generated in such a way to create oberservable patterns that form impressions of a macro scale image.

Due to the optimized toolpath generated, the aeshetic value added in such operation is much larger than the extra electricity and time costs than traditional analogue and manual wood planing.

Towards 100% Recycling

Construction waste generated in Hong Kong, both from construction and demolition, is divided into two groups: inert and non-inert where inert materials accounts for around 90% and non-inert the rest. While inert materials such as debris, bitumen and concrete are reused in land reclamation site formation and even construction, non-inert materials are often disposed in landfills with pollution followed. Recycling this 10% of construction waste will work towards achieving a zero waste city.

The US Environmental Protection Agency has developed a Waste Reduction Model called WARM for the assessment of material life cycles and greenhouse gas emissions. Hong Kong is lagged behind in the implementation of policies and incentives. Perhaps we can start advocating the client and the public about the importance of recycling materials with this design & fabrication project.